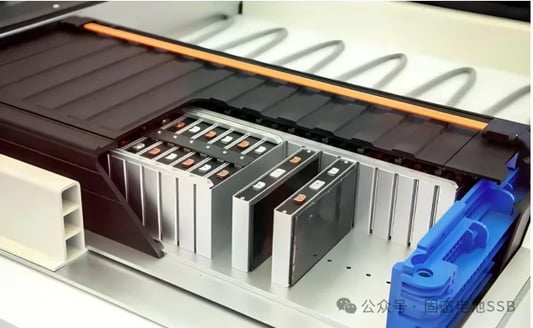

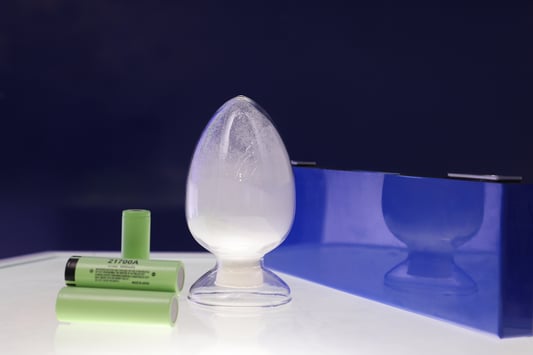

At the beginning of the 20th century, the range of new energy vehicles was only 40 kilometers. Today, many new energy vehicles can travel over 700 kilometers on a single charge, thanks to the revolution in battery technology, which has driven rapid industrial development. Today, we will decrypt the "code" behind the range of new energy vehicles and understand the core functional material behind it, PVDF lithium battery binder.Decrypting the low-key hero in lithium batteries - lithium battery binder The lithium battery we are familiar with mainly consists of electrodes (positive and negative electrodes), electrolytes, and separators. During the charging and discharging process of the battery, lithium ions (Li+) are repeatedly inserted and extracted between the positive and negative electrodes, while electrons form a current through an external circuit.Where is the lithium battery binder? ☟ The lithium battery binder is "stuck" on the positive electrode sheet ☟Why is a binder needed? This is because the electrode is composed of a metal electrode sheet and electrode material attached to it, and there is no adhesive force inside the electrode material or between the electrode material and the metal electrode sheet. The binder is needed for "bonding" to maintain the integrity of the electrode structure. How important is the lithium battery binder? The lithium battery binder is an indispensable component in lithium batteries. Although it accounts for a small proportion, it is the main source of the overall mechanical performance of the electrode, and it has a significant impact on the production process of the electrode and the electrochemical performance of the battery.The main functions of lithium battery binders: ▶▶ Bonding active materials, conductive agents, and current collectors to maintain electrode structure integrity ▶▶ Acting as a dispersant or thickener to improve the uniformity of electrode components In summary, lithium battery binders, which account for only about 1% of the total cost of lithium batteries, play a significant role in the core performance of batteries such as cycle life, charge-discharge capacity, rate capability, and so on.Why choose PVDF as the lithium battery binder? Lithium battery binders not only carry so many responsibilities, but also need to work stably in extremely harsh environments for a long time. In daily life, the adhesives we use are mostly hydrocarbon polymers, which have the advantages of low cost, quick drying, and strong bonding strength. For example, pressure-sensitive adhesive (acrylic resin) and super glue (alpha-cyanoacrylate) are commonly used. However, the internal environment of lithium batteries is harsh. The binders and electrode materials are constantly immersed in the electrolyte, subjected to various electrochemical reactions, and required to maintain long-term stability within the working voltage range of the electrodes. Ordinary hydrocarbon "glues" are either dissolved in the electrolyte or oxidized by the electrochemical environment. The task of bonding lithium batteries is not something that general adhesives can handle. This is where PVDF comes in. PVDF (polyvinylidene fluoride) is a special fluorinated olefin polymer. Compared to the "king" of olefin polymers polyethylene, half of the hydrogen atoms in PVDF are replaced by fluorine atoms, forming carbon-fluorine bonds instead of carbon-hydrogen bonds in polyethylene. These bonds have a high energy, are very strong and difficult to break, making PVDF much more stable than general hydrocarbon polymers. In addition, because fluorine atoms have strong electronegativity, PVDF is highly polar and can dissolve in some strong polar solvents such as amides, forming a flow system of electrode materials, binders, and solvents for coating on electrode sheets. Witness the Four Winning Moves of PVDF #"Stable" PVDF has good chemical stability, is acid-resistant and oxidation-reduction-resistant, will not be dissolved by the electrolyte, will not be oxidized under high voltage conditions, and will not react or deteriorate during storage and cycling. #"Bonding" If the bonding strength of the binder is insufficient, the electrode material may detach from the electrode sheet after multiple charge-discharge cycles, rendering the battery unable to store energy and leading to the entire battery being scrapped. Compared to tetrafluorine binders, PVDF has both carbon-fluorine bonds and carbon-hydrogen bonds, forming hydrogen bonds with the oxygen elements on the positive electrode to firmly adhere the positive electrode particles. #"Flexible" PVDF has enough flexibility to ensure that the active materials do not detach during repeated expansion and contraction, and the binding between electrode particles is not destroyed. #"Dissolve" PVDF lithium battery binders have good solubility, fast dissolution speed, and high solubility. After PVDF is dissolved into a solution, it can be evenly dispersed into the positive electrode material and the surface of the electrode sheet, effectively bonding the active materials uniformly to the current collector.Amp New Energy Technology Co., Ltd. What's the big difference in PVDF lithium battery binderInnovation-driven, high-end products achieve domestic substitution Amp New Energy Technology Co., Ltd. has been deeply involved in fluorine chemical industry for more than 70 years, with more than 40 years of deep accumulation in the field of PVDF research and production technology, and has presided over and participated in many scientific and technological research projects. Since 2009, Amp New Energy Technology Co., Ltd. has started to develop PVDF products specifically for lithium battery binders, successively developing 5 grades of PVDF products including emulsion, suspension, and modified types, and has accumulated a number of leading technologies and "Know-How" in VDF monomer synthesis, PVDF polymerization process formulation, and resin scale production. It has many "unique skills" in areas such as fluoropolymer quasi-steady-state polymerization, constant ratio copolymer modification, and condensed phase structure analysis. Innovative mechanism, efficient operation of "research, production, sales, and inspection"Amp New Energy Technology Co., Ltd. has a complete set of small-scale, medium-scale, and industrialization supporting facilities, and integrates product development, performance evaluation, application research, production, and sales in one. The project team focuses on product design and process manufacturing, with customer application requirements as the guide, and creates sustainable innovation capabilities. At the beginning of 2021, the domestic new energy electric vehicle industry ushered in an explosive growth market situation, and the demand for PVDF from lithium battery manufacturers quickly increased. The project team took rapid action, conducted targeted product small-scale experiments to prepare samples, and achieved the formalization of a new green and high-performance emulsion method PVDF grade in just 3 months; and overcame the scalability issues of synthetic process amplification. While optimizing experiments and saving production costs, the new product was efficiently scaled up for production, successfully integrating the product into the supply chain system of leading enterprises in the lithium battery industry. At the same time, Amp New Energy Technology Co., Ltd. is also one of the few PVDF manufacturers in China that provide evaluation laboratories for lithium battery applications. The application evaluation laboratory has the ability to evaluate most of the downstream lithium battery customer trial lines, test indicators such as solid content, stability, rheological properties of lithium battery slurry containing PVDF, and coat them into electrode sheets to evaluate the relevant performance of the electrode sheets. It is equivalent to moving some of the evaluation capabilities of lithium battery customers into the laboratory, greatly reducing the distance between products and applications, and achieving efficient connection with the market.

02. April, 2024