Unlocking the Power of Conductive Carbon Black

Conductive Carbon Black is a fascinating material that has revolutionized multiple industries. Its unique properties make it an indispensable component in various applications. In this article, we will explore the different prospects of Conductive Carbon Black and understand its importance in today's world.

1. Introduction to Conductive Carbon Black

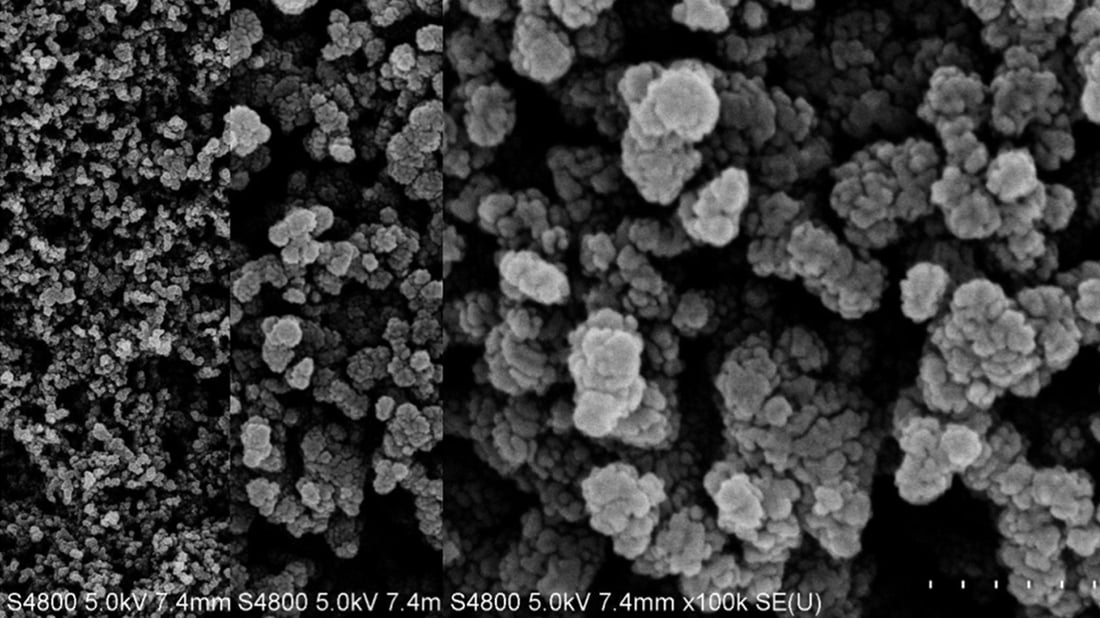

Conductive Carbon Black is a form of carbon that possesses excellent electrical conductivity. It is produced by the thermal decomposition of hydrocarbons, such as natural gas or petroleum oil, in the absence of air. The resulting material is a fine powder composed of small particles.

Due to its conductive properties, Conductive Carbon Black finds extensive use as a filler in numerous applications where electrical conductivity is required.

2. Enhancing Electrical Conductivity

One of the primary uses of Conductive Carbon Black is to enhance the electrical conductivity of materials. When added to polymers, rubber, or plastics, it forms a conductive network, allowing the flow of electricity.

This property makes Conductive Carbon Black a vital additive in the production of products such as cables, wires, and electronic components. It ensures efficient transmission of electrical signals and prevents static buildup.

3. Reinforcing Mechanical Strength

In addition to its electrical conductivity, Conductive Carbon Black also offers significant mechanical reinforcement. When incorporated into materials, it improves their strength, durability, and resistance to wear and tear.

For example, in the manufacturing of tires, Conductive Carbon Black is added to the rubber compound to enhance its mechanical properties. The resulting tires exhibit improved traction, better resistance to abrasion, and increased overall lifespan.

4. UV Protection

Conductive Carbon Black is highly effective in providing ultraviolet (UV) protection. It absorbs and disperses UV radiation, preventing damage caused by prolonged exposure to sunlight.

As a result, Conductive Carbon Black is widely used in the production of outdoor products, such as plastic films, coatings, and paints. These products benefit from the UV-blocking properties of Conductive Carbon Black, which helps preserve their color, integrity, and longevity.

5. Conductive Inks and Coatings

Conductive Carbon Black also plays a crucial role in the formulation of conductive inks and coatings. These inks and coatings are used in various applications, including printed electronics, solar panels, and touchscreens.

By incorporating Conductive Carbon Black into the ink or coating formulation, manufacturers can achieve high electrical conductivity and ensure the proper functioning of these electronic devices.

6. Electrostatic Dissipation

Electrostatic discharge can cause damage to sensitive electronic components. However, by utilizing Conductive Carbon Black, manufacturers can create materials that facilitate electrostatic dissipation.

Products such as flooring, workbenches, and packaging materials can be made conductive with the addition of Conductive Carbon Black. This ensures that any static charge is safely dissipated, protecting valuable electronic equipment from potential harm.

7. Conductive Adhesives and Sealants

Conductive Carbon Black is also used in the production of conductive adhesives and sealants. These materials are essential in various industries, including electronics, aerospace, and automotive.

Conductive adhesives and sealants enable the bonding and sealing of components while maintaining electrical conductivity. This is particularly valuable in applications where electrical connections need to be established, such as bonding electronic circuits or sealing electromagnetic shielding.

8. Antistatic Additives

Conductive Carbon Black is commonly used as an antistatic additive. When incorporated into materials like plastics or textiles, it prevents the buildup of static charges, reducing the risk of electrostatic discharge.

Products such as computer casings, automotive interiors, and clothing benefit from the antistatic properties of Conductive Carbon Black. These materials help protect sensitive electronic devices and ensure user safety.

9. Conductive Rubber Products

Conductive Carbon Black is a key component in the manufacturing of conductive rubber products. Conductive rubber is highly resilient, durable, and exhibits excellent electrical conductivity.

These properties make conductive rubber ideal for applications such as gaskets, O-rings, and seals in electrical systems. It ensures proper electrical grounding, prevents leakage, and maintains the integrity of the system.

10. Emerging Applications

The versatility of Conductive Carbon Black continues to drive its adoption in new and exciting applications. Researchers are exploring its use in areas such as flexible electronics, energy storage devices, and conductive composites.

As technology evolves, Conductive Carbon Black is expected to play an increasingly significant role in shaping the future of various industries.