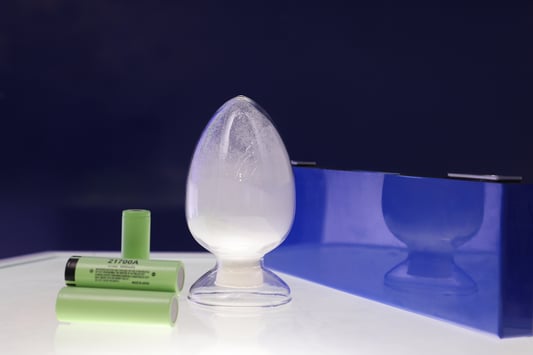

Why is PVDF used for membranes?A membrane is a thin, selective barrier that separates two different phases, such as gases or liquids. Membranes are widely used in various applications, including water purification, gas separation, and drug delivery systems. One of the key materials used for manufacturing membranes is Polyvinylidene fluoride (PVDF). PVDF offers several desirable properties that make it an excellent choice for membrane applications. In this article, we will explore the reasons why PVDF is used for membranes.Durability and Chemical ResistancePVDF is known for its exceptional durability and chemical resistance. It can withstand exposure to a wide range of harsh chemicals, including acids, bases, and organic solvents. This makes PVDF membranes highly resistant to degradation, ensuring their longevity and reliability in various applications. Whether it is filtering aggressive solvents or treating wastewater, PVDF membranes can maintain their performance even in challenging environments.High Purity FiltrationPVDF membranes offer high purity filtration, making them ideal for applications where the removal of contaminants is critical. The structure of PVDF membranes allows for precise control over pore size, enabling the retention of particles and molecules of different sizes. This makes PVDF membranes effective in removing bacteria, viruses, and other microorganisms from water or air. The high purity filtration capability of PVDF membranes makes them valuable in industries such as pharmaceuticals and electronics.Excellent Mechanical StrengthPVDF membranes possess excellent mechanical strength, which is crucial for their performance in filtration applications. The strong and robust nature of PVDF allows the membranes to withstand high pressures and maintain their integrity even in demanding conditions. This mechanical strength ensures that PVDF membranes do not collapse or deform under the operating pressures, providing consistent and reliable filtration performance.Thermal StabilityPVDF membranes exhibit excellent thermal stability, allowing them to be used in applications where elevated temperatures are involved. They can withstand a wide temperature range, from cryogenic temperatures to higher temperatures depending on the specific grade of PVDF used. This thermal stability of PVDF membranes enables their use in processes that require heat sterilization or where exposure to high temperatures is necessary for efficient operation.HydrophobicityPVDF membranes are inherently hydrophobic, meaning they repel water. This hydrophobic nature of PVDF makes it suitable for applications where water wetting can negatively impact performance. For example, in gas separation processes, hydrophobic PVDF membranes prevent wetting by water vapor, allowing for efficient separation of different gases. The hydrophobicity of PVDF also contributes to the self-cleaning properties of the membranes, reducing fouling and improving overall performance.Chemical CompatibilityAnother advantage of PVDF membranes is their compatibility with a wide range of chemicals. PVDF is resistant to many organic solvents, acids, and bases, making it suitable for applications involving aggressive chemical environments. This chemical compatibility allows PVDF membranes to be used in processes such as solvent filtration, where other materials may fail or degrade over time.BiocompatibilityPVDF membranes are biocompatible, meaning they are compatible with living tissues or organisms without causing harmful effects. This property makes PVDF membranes suitable for medical applications, such as drug delivery systems or blood filtration. The biocompatibility of PVDF ensures that the membranes can be safely used in contact with biological fluids or tissues, without causing adverse reactions.Easy to CleanPVDF membranes are relatively easy to clean compared to other membrane materials. Their hydrophobic nature prevents the adsorption of contaminants, making it easier to remove debris or fouling from the surface. PVDF membranes can be cleaned using various methods, including backwashing, chemical cleaning, or a combination of both. This ease of cleaning contributes to the longevity and efficient performance of PVDF membranes in filtration applications.Wide Range of ApplicationsThe exceptional properties of PVDF membranes make them suitable for a wide range of applications. They are extensively used in water treatment systems, including desalination, wastewater treatment, and drinking water purification. PVDF membranes also find applications in the food and beverage industry, pharmaceutical manufacturing, biotechnology, and electronic industries. The versatility of PVDF membranes makes them a popular choice for diverse filtration needs.ConclusionPVDF membranes offer a unique combination of properties that make them highly desirable for membrane applications. Their durability, chemical resistance, high purity filtration, mechanical strength, thermal stability, hydrophobicity, chemical compatibility, biocompatibility, ease of cleaning, and wide range of applications make PVDF an excellent choice for membrane production. Whether it is water purification, gas separation, or medical filtration, PVDF membranes provide reliable and efficient performance.Quote InquiryContact Us Now!

14. April, 2024